Zero risk of contamination

Whether your activities are in pharmaceutical production,food & beverage, critical electronics or in a similarly exacting industry, air quality is paramount for your end product and production process. Atlas Copco’s AQ oil-free compressors eliminate the risks of oil contamination.

Reduced energy costs

With energy amounting to over 70% of a compressor’s lifecycle costs (LCC), its importance is clear. The most efficient compressed air solution optimizes the pressure, volume and air treatment equipment for each production process. Atlas Copco’s AQ compressors provide you with the ultimate all-in-one package to reduce your electricity bill to a minimum.

Renowned expertise

Drawing on vast experience and continuous technological innovations, Atlas Copco has been leading the industry in oil-free compressed air technology for over sixty years.With the protection of your application in mind, Atlas Copco has designed its AQ range to offer the superb 100% oil-free quality air you are in need of.

ENGINEERED TO MEET YOUR NEEDS

At Atlas Copco we aim to provide you with compressors that fulfill and even exceed your expectations and demands. Built as the result of decades of experience in oil-free design and manufacturing, the AQ range of oil-free screw compressors gives you all of this experience and knowledge in a class leading package.

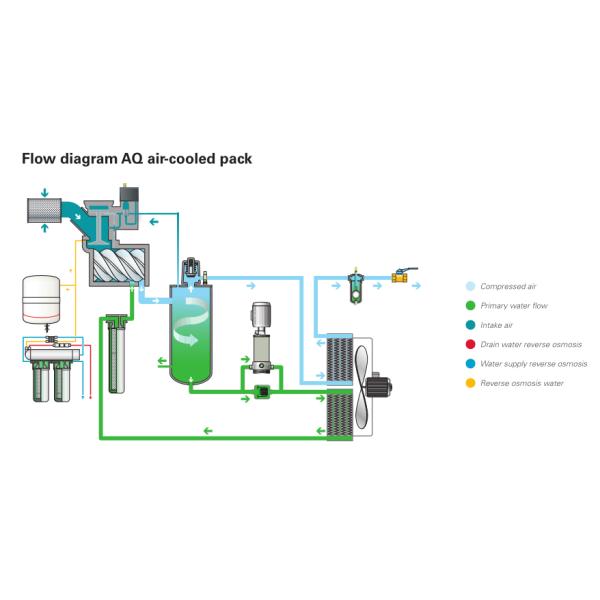

1.Water-injected screw element

• Highly energy-efficient thanks to low temperatures.

• Water-lubricated, grease-free bearings.

• In-house design and manufacturing.

• Working pressure up to 13 bar.

2.Water filter

• Ensuring a constant supply of clean water.

• The filtration capability equals 10 micron throughout the filter’s lifetime.

3.Heavy-duty air filter

• Protects the compressor components by removing 99.9% of dirt particles down to 3 microns.

• Differential inlet pressure for proactive maintenance while minimizing pressure drop.

4.Separator vessel

• Stainless steel water separator vessel for separation via centrifugal and gravity forces.

• Three sensors included for precise water regulation.

5.Induction motor

• IP55 induction motor, flange-mounted for perfect alignment.

• Combined with direct driven arrangement for superior energy efficiency.

6.Reverse osmosis system

• The built-in reverse osmosis system provides a reliable supply of high quality water, ensuring autonomy and continuous operation.

7.Air-cooled fan and water-cooler

• Air and water-cooled variants are available throughout the range.

• Small footprint and installation thanks to built-in heat exchangers.

• Water-cooled units provide a continuous air temperature at the dryer inlet of less than 55°C (131°F).

8.Integrated highly efficient dryer

• Excellence in air quality.

• 50% reduction in energy consumption compared to traditional dryers.

• Zero ozone depletion.

9.Elektronikon® Graphic

• Advanced Elektronikon® Graphic control and monitoring system,designed for integration in a (remote) process control system.

10.Sound insulated canopy

• No separate compressor room is required as the sound insulated canopy allows for installation in most working environments.

11.Innovative Neos frequency converters

• IP5x protection class

• Robust aluminium housing for trouble-free operation in harsh conditions

• Fewer parts: compact and easy to use

PROVEN TECHNOLOGY

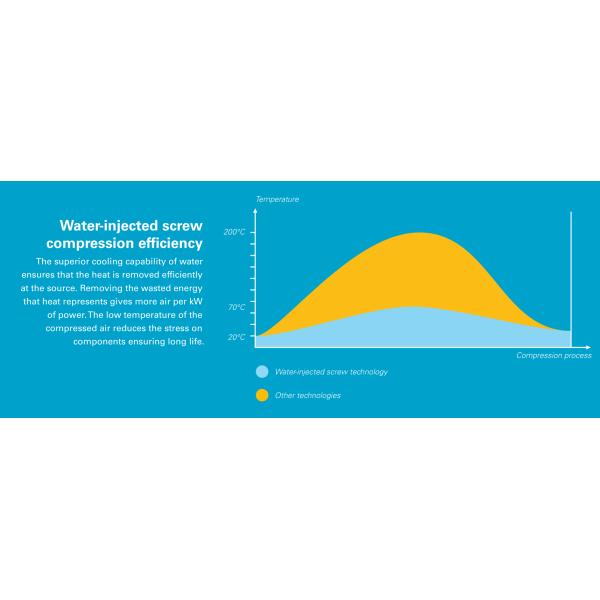

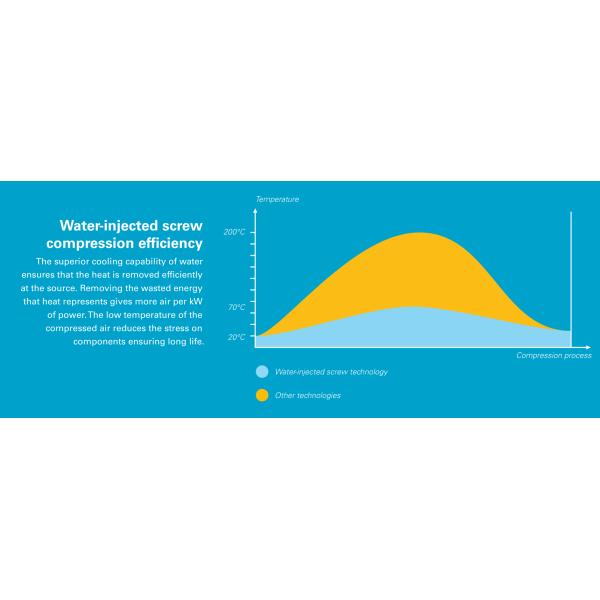

At the heart of the new AQ range is a unique water-injected screw element working highly efficient near isothermal compression. The polymer ceramic rotors with their optimized rotor profile are supported by water-lubricated bearings, ensuring that no oil whatsoever can contaminate the compression element,thereby producing pure oil-free air.

Rotors

A highly efficient compression process is achieved thanks to high quality polymer mould ceramic rotors with optimum profiling. The combination

of corrosion-free, high efficiency raw material and water lubrication results in a longer lifespan.

Element housing

Strength and durability are ensured as a result of the aluminium bronze element housing without risk of corrosion within the element.

Element bearings

The use of hydrodynamic bearings ensure long life as no physical contact is made within the bearing itself, it simply glides on a film of water removing the need for any oil or grease lubrication.

Superior water-injected screw element

• Increased free air delivery.

• Low specific energy consumption.

• Near isothermal compression process.

• Pressure ratings of 7, 10 and 13 bar.

The highly effective cooling capabilities of water combined with precision engineering ensure the supreme energy efficiency of the AQ compressors.

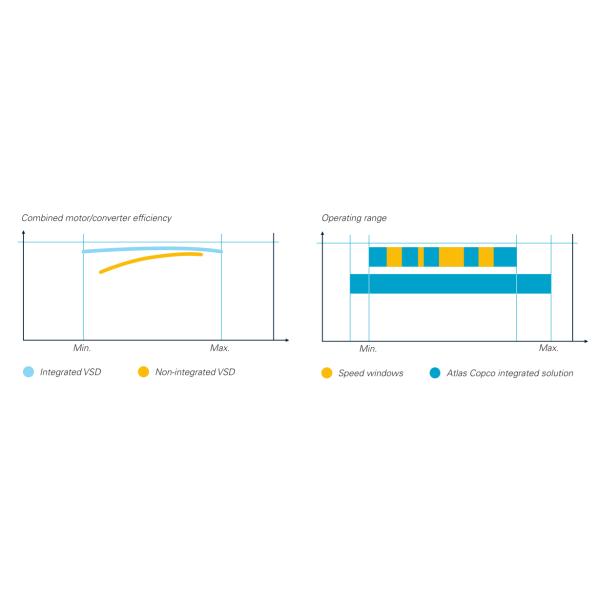

Why Atlas Copco Variable Speed Drive technology?

• On average 35% energy savings during fluctuations in production demand with an extensive turndown range.

• Integrated Elektronikon Graphic controller controls the motor speed and high efficiency frequency inverter.

• No wasted idling times or blow-off losses in normal operation.

• Compressor can start/stop under full system pressure without the need to unload with special VSD motor.

• Eliminates peak current penalty during start-up.

• Minimizes system leakage due to a lower system pressure.

• EMC Compliance to directives (2004/108/EG).

TECHNICAL SPECIFICATIONS

| Type | Working pressure | FAD | Motor Power | Noise | Weight(kg/lbs) |

| bar(g) | psig | I/s | m³/min | cfm | kW | hp | dB(A) | P | FF |

| Water-cooled | | | | | | | | | | |

| AQ15VSD A | 4 | 58 | 22-50 | 1.29-3.01 | 46-106 | 15 | 20 | 67 | 650/1433 | 700/1543 |

| 7 | 102 | 22-46 | 1.34-2.78 | 47-98 |

| 10 | 145 | 23-38 | 1.35-2.29 | 48-81 |

| 11 | 160 | 23-35 | 1.32-32.10 | 47-74 |

| 12.75 | 185 | 22-30 | 1.30-1.81 | 46-64 |

| AQ18VSDA | 4 | 58 | 22-62 | 1.29-3.73 | 46-132 | 18 | 25 | 69 | 650/1433 | 700/1543 |

| 7 | 102 | 22-54 | 1.34-3.22 | 47-114 |

| 10 | 145 | 23-45 | 1.35-2.68 | 48-95 |

| 11 | 160 | 22-42 | 1.32-2.52 | 47-89 |

| 12.75 | 185 | 22-37 | 1.30-2.19 | 46-77 |

| AQ22VSDA | 4 | 58 | 22-66 | 1.31-3.95 | 46-139 | 22 | 30 | 70 | 740/1631 | 800/1764 |

| 7 | 102 | 23-66 | 1.35-3.93 | 48-139 |

| 10 | 145 | 23-54 | 1.35-3.25 | 48-115 |

| 11 | 160 | 22-51 | 1.32-3.06 | 47-108 |

| 12.75 | 185 | 22-44 | 1.31-2.66 | 46-94 |

| AQ30VSDA | 4 | 58 | 22-83 | 1.31-5.00 | 46-177 | 30 | 40 | 72 | 740/1631 | 810/1786 |

| 7 | 102 | 23-83 | 1.35-4.96 | 48-175 |

| 10 | 145 | 23-77 | 1.35-4.60 | 48-163 |

| 11 | 160 | 22-74 | 1.32-4.44 | 47-157 |

| 12.75 | 185 | 22-64 | 1.31-3.85 | 46-136 |

| AQ37VSDA | 4 | 58 | 42-108 | 2.50-6.45 | 88-228 | 37 | 50 | 69 | 1300/2866 | 1410/3108 |

| 7 | 102 | 39-105 | 2.35-6.31 | 83-223 |

| 10 | 145 | 51-91 | 3.07-5.45 | 108-193 |

| 11 | 160 | 55-84 | 3.27-5.03 | 116-178 |

| 12.75 | 185 | 61-76 | 3.63-4.58 | 128-162 |

| AQ45VSDA | 4 | 58 | 44-130 | 2.62-7.79 | 93-275 | 45 | 60 | 72 | 1300/2866 | 1410/3108 |

| 7 | 102 | 40-127 | 2.42-7.64 | 86-270 |

| 10 | 145 | 53-105 | 3.20-6.28 | 113-222 |

| 11 | 160 | 57-101 | 3.42-6.08 | 121-215 |

| 12.75 | 185 | 66-89 | 3.97-5.33 | 140-188 |

| AQ55VSDA | 4 | 58 | 44-155 | 2.62-9.31 | 93-329 | 55 | 75 | 75 | 1300/2866 | 1410/3108 |

| 7 | 102 | 40-152 | 2.42-9.10 | 86-321 |

| 10 | 145 | 53-135 | 3.20-8.08 | 113-285 |

| 11 | 160 | 57-127 | 3.42-7.62 | 121-269 |

| 12.75 | 185 | 66-115 | 3.97-6.92 | 140-245 |

| Type | Working pressure | FAD | Motor Power | Noise | Weight(kg/lbs) |

| bar(g) | psig | I/s | m³/min | cfm | kW | hp | dB(A) | P | FF |

| Water-cooled | | | | | | | | | | |

| AQ15VSD W | 4 | 58 | 22-50 | 1.29-3.02 | 46-107 | 15 | 20 | 64 | 542/1195 | 592/1305 |

| 7 | 102 | 22-46 | 1.34-2.78 | 47-98 |

| 10 | 145 | 23-38 | 1.35-2.29 | 48-81 |

| 11 | 160 | 23-36 | 1.38-2.16 | 49-76 |

| 12.75 | 185 | 22-30 | 1.30-1.81 | 46-64 |

| AQ18VSD W | 4 | 58 | 22-62 | 1.29-3.74 | 46-132 | 18 | 25 | 66 | 542/1195 | 592/1305 |

| 7 | 102 | 22-54 | 1.34-3.22 | 47-114 |

| 10 | 145 | 23-45 | 1.35-2.68 | 48-95 |

| 11 | 160 | 18-35 | 1.08-2.10 | 38-74 |

| 12.75 | 185 | 22-37 | 1.30-2.19 | 46-77 |

| AQ22VSD W | 4 | 58 | 21-67 | 1.28-4.03 | 45-142 | 22 | 30 | 67 | 632/1393 | 692/1526 |

| 7 | 102 | 23-65 | 1.35-3.95 | 48-139 |

| 10 | 145 | 23-55 | 1.36-3.31 | 48-117 |

| 11 | 160 | 22-52 | 1.32-3.12 | 47-110 |

| 12.75 | 185 | 22-46 | 1.32-2.77 | 47-98 |

| AQ30VSD W | 4 | 58 | 21-82 | 1.28-4.91 | 45-173 | 30 | 40 | 69 | 632/1393 | 702/1548 |

| 7 | 102 | 23-83 | 1.35-4.99 | 48-176 |

| 10 | 145 | 23-78 | 1.36-4.66 | 48-165 |

| 11 | 160 | 23-77 | 1.38-4.62 | 49-163 |

| 12.75 | 185 | 22-66 | 1.32-3.98 | 47-140 |

| AQ37VSD W | 4 | 58 | 45-113 | 2.69-6.77 | 95-239 | 37 | 50 | 66 | 1186/2614 | 1296/2857 |

| 7 | 102 | 42-110 | 2.51-6.61 | 89-233 |

| 10 | 145 | 54-93 | 3.23-5.56 | 114-196 |

| 11 | 160 | 60-87 | 3.59-524 | 127-185 |

| 12.75 | 185 | 69-78 | 4.12-4.70 | 146-166 |

| AQ45VSD W | 4 | 58 | 45-135 | 2.69-8.09 | 95-286 | 45 | 60 | 69 | 1186/2514 | 1296/2857 |

| 7 | 102 | 42-132 | 2.51-7.94 | 89-281 |

| 10 | 145 | 54-108 | 3.23-6.46 | 114-228 |

| 11 | 160 | 59-104 | 3.55-6.22 | 126-220 |

| 12.75 | 185 | 69-93 | 4.12-5.56 | 146-196 |

| AQ55VSD W | 4 | 58 | 45-160 | 2.69-9.60 | 95-339 | 55 | 75 | 72 | 1186/2614 | 1296/2857 |

| 7 | 102 | 42-158 | 2.51-9.50 | 89-335 |

| 10 | 145 | 54-140 | 3.23-8.42 | 114-298 |

| 11 | 160 | 59-133 | 3.56-8.00 | 126-283 |

| 12.75 | 185 | 69-120 | 4.12-7.22 | 146-255 |

Dimensions

| Type | Air-cooled | Water-cooled |

| L(mm) | W(mm) | H(mm) | L(mm) | W(mm) | H(mm) |

| AQ 15-30VSD | 1966 | 974 | 1500 | 1966 | 974 | 1500 |

| AQ 37-55VSD | 2435 | 965 | 1839 | 2435 | 965 | 1839 |